Bio-Circular Avocado Value Chains: Turning waste into inputs and energy for rural enterprises

A story from Uganda: from fruit to fertiliser, from seed to fuel. Nothing is wasted.

Avocado farming can mean more than fruit piled onto a truck after a long and arduous season. With a bio-circular mindset, every by-product becomes an input for the next process.

This unique tree crop lends itself well to sustainability practices such as those listed here - and for farmers of other crops, there’s a lot that can learnt and taken away.

With a circular mindset, every loop tightens. Every cost is inspected for its potential to feed value back into the system - adding value that would otherwise have been lost.

It’s a powerful sustainability practice. When done right it becomes a flywheel for improvements and high-impact optimisations. Additionally, it can mean a gentler way of farming - a benefit for the planet.

Let’s outline a few concepts, provide basic examples, and hopefully get you thinking about how you can incorporate this mindset in your own operations or workflows - whether you are in the Avocado industry or not.

Reduce, Reinvest, Repeat.

Reduce inputs where you can, recycle and up-cycle what you already have. Produce energy and future value out of waste - doing this as close to the source as possible.

Reinvest energy, resources, and savings back into producing yield, quality, and the support of your people and communities.

Repeat the process. Gain momentum, and feed the flywheel. This is how the cyclic rhythm of sustainability starts.

But let’s be frank for a second….

It’s a tricky endeavour to practice this type of flywheel approach at scale, for sure. So start small, initiate a pilot project, then work on scaling it up over time. Also, I strongly believe that small and mid-sized enterprises are flexible enough to implement bio-circular operational shifts with greater ease compared to larger operations.

Agricultural areas of Uganda, Kenya, India, Latin America, Asia, South Africa, even California in the US: Operations can find, manage, and benefit from these concepts from day-1, while the benefits compound with consistent practice.

A strong lever for agri-operations who ship products locally or abroad, and who count on every dollar, peso, rand, or rupee that hits their bottom line.

What “bio-circular” means in avocado speak

Biology powers the cycle; while a circular design curbs unnecessary waste.

Each waste-stream is mapped, routed to a physical, biological, or thermo-chemical process, and value is returned to the orchard, ecosystem, or community. Oftentimes all three. Of course, the aim is to turn each stream into an asset.

Typical “byproducts” utilised from the field, fresh fruit production, and oil mills:

Pruning branches (chipped/mulched)

Reject fruit and fruit pulp

Seeds (AKA pips/pits)

Peels and press cakes

Wash water and oily effluent

Low-quality fruit: Avocado fruit that are too small or does not meet market standards for fresh consumption can be redirected toward oil extraction or other refining applications. No waste, only redirection.

Pulp residue: In the oil extraction process, especially mechanical methods, a residual avocado pulp is produced. This can be used as biofuel, composting material, or dried and incorporated into livestock feed.

Press cakes: From avocado oil production, these are a byproduct of the mechanical extraction process and are rich in valuable compounds. Sometimes used for animal feed and increasingly explored for use in cosmetics and other value-added products due to high antioxidant content. So there are two roads here… producing a new product to sell, or utilising this byproduct back on site (see notes on pulp residue above).

The Water loop: clean up, loop back

Oil mill effluent and wash water should not leave the site without treatment, and can be reused.

Pair a small anaerobic reactor with a gravel-reed wetland or a biofilter.

Treated water irrigates cover crops or feeds back to washing facilities.

The goal is zero odour, zero discharge, and documented reuse. It’s a story you know already: water is one of our most precious resources - it’s good practice to reuse wherever you can.

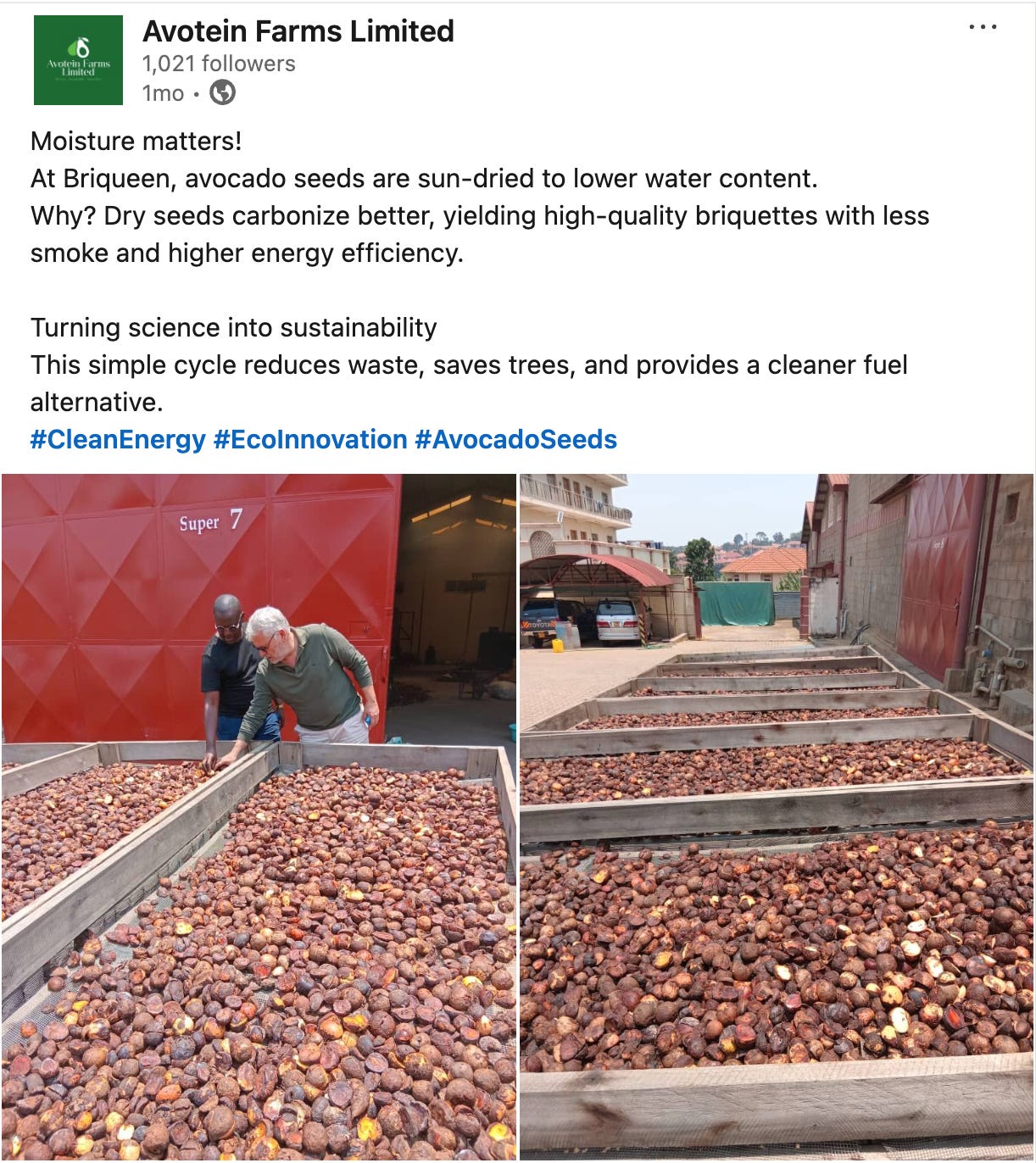

Seed to heat: Briquettes that replace charcoal

Avocado seeds are dense energy. Dry them properly, carbonise or compress, and you have a cleaner fuel that displaces charcoal and firewood.

Several operators are proving this innovation at scale, including the Briqueen (*by Avotein) which is a seed-briquette line from Uganda. They collect pits from oil factories and convert them into fuel for households and canteens.

Drying matters; and a lower moisture improves carbonisation while reducing smoke when the briquettes are finally used for heating.

Avotein Farms Limited are thus making great strides in turning science into sustainability within their production chain. Fantastic to see.

1-Minute Briquette ROI framework

Write down your once-off setup cost.

Work out how many kilos of briquettes you’ll make each month.

Decide how many you’ll use on the farm and how many you’ll sell.

Give each kilo a value: either the local charcoal price per kg (for the kilos you replace on-farm) or your selling price per kg (for the kilos you sell).

Subtract your monthly running costs.

The money left over each month is your margin.

Payback is just setup cost divided by that monthly margin.

You can start with a pilot dryer and press. Prove substitution in your own kitchen or staff housing first. Tweak for improvements, then expand to nearby villages only when logistics are stable and you’re happy with the product.

Ultra-formulas (Optional)

Monthly margin = (Used_kg × Charcoal_price) + (Sold_kg × Selling_price) − Monthly_running_costs

Payback (months) = Setup_cost ÷ Monthly_margin

Margin per kg (handy for break-even) = Average_price_per_kg − Variable_cost_per_kg

Break-even volume (kg/month) = Monthly_running_costs ÷ Margin_per_kg

Tiny worked example (swap with your numbers)

Setup cost: $5,000

You make 1,000 kg/month

Use 600 kg on-farm – value $1.00/kg

Sell 400 kg at $1.00/kg

Monthly running costs (labour, bags, power, maintenance): $400

Monthly margin

= (600 × 1.00) + (400 × 1.00) − 400

= 600 + 400 − 400 = $600

Payback

= 5,000 ÷ 600 ≈ 8.3 months

That’s it. No fancy maths; just kilos, local prices, and two quick sums.

Using pulp, peels, and press cake for biogas, compost, and pectin production

Biogas broadly speaking is a renewable energy source generated from organic waste that typically fuels a biogas boiler or a small biogas generator (genset) producing heat or electricity.

In your own bio-circular avocado setup, a small biogas-ready genset could turn pulpy waste into electricity (via the digester) and heat for hot water; while you get (1) energy and (2) a nutrient-rich digestate in return - added value for the orchards.

As biogas runs a boiler or a small genset, the digestate returns to the farming system as a nutrient-rich fertiliser.

Fruit wastes are well-documented biogas substrates; recent work also looks specifically at avocado oil by-products and their digestion behaviour.

Moreover, avocado peels carry valuable compounds too.

There are two routes that stand out:

Pectin extraction for food and jam makers; a growing literature base shows workable extraction pathways from fruit peels, including avocado.

Phenolic-rich extracts for natural antioxidant applications; ultrasound and microwave-assisted extractions are being refined for avocado peel.

If you are early on the capability curve, don’t distress - composting and vermicomposting are the right first steps when it comes to utilising excess pulp and press cake waste. Keep it modular. Layer in extraction when you can once volumes, budget, skills, and infrastructure allow.

Black Soldier Fly: Turning harvest rejects into protein and plant power

Black soldier fly larvae (BSFL) love fruit waste. Avocado rejects, pulpy press cake, even bits of peel. They convert wet waste into two saleable products: protein and insect frass. They also shrink your landfill footprint in weeks, not months.

Why BSFL fit avocado operations

High waste reduction. Well-run BSFL systems routinely cut substrate mass by 55–70 %. Higher rates are possible with good feed prep and density control.

Proven on avocado residues. Trials with rotten avocado as a primary feedstock show strong larval growth and good assimilation efficiency. Practical operators see rapid breakdown of whole fruits.

Valuable outputs. The larvae become a high-protein feed ingredient for poultry and aquaculture. The frass is a nutrient-rich amendment with clear plant-growth and soil-health benefits.

How to make the loop work on-farm

Segregate and size the feed. Keep plastics and string out. Break large fruits. Mix pulpy avocado with drier trimmings to avoid a soggy bed. Aim for a moist crumb, not sludge.

Load at the right density. Start with conservative larval densities. Scale once your team can keep beds aerated and odour-free.

Harvest on a schedule. Ten to fourteen days is typical for fruit-rich feeds. Stop earlier if you want higher protein. Go longer if oil yield is your target. Keep a simple log of days, weight in, weight out.

Finish the frass. Screen out larvae and skins. Cure the frass briefly before field application. Trial rates in nursery trays first. Then band-apply in the orchard.

ROI steps you can run this week

Inputs:

Kg of avocado waste per day

Labour hours for sorting and feeding

Crates, mesh, shallow trays

Starter larvae

Outputs:

Kg of fresh larvae per day

Kg of screened frass per day

Kg of avocado waste diverted from landfill or paid collection

Where the value comes from:

Waste handling savings: what you no longer pay for hauling, dumping, or burning wet waste

Fertiliser displacement: frass replacing part of your chemical fertiliser in trial blocks

Optional sales: sell surplus larvae or frass locally if there is demand

Basic monthly margin = Waste_handling_savings + Fertiliser_displacement_value + Optional_sales − Monthly_running_costs

Payback (months) = Setup_cost ÷ Monthly_margin

Tip: Start by counting only the first two value streams (waste savings + fertiliser displacement). Treat any sales as upside once your process is steady.

Practical guardrails

Keep the beds shallow. Oxygen matters.

Balance wet avocado pulp with drier organics to avoid anaerobic pockets.

Sun-dry oversaturated feed for a day if needed. Shade nets help too.

Document everything, and do your own research.

But most importantly, take action.

Bottom line: BSFL turn avocado rejects into a circular bundle of protein for birds and a soil-building amendment for trees. Less waste. More value.

Data-first farming: Put inputs where they pay

Circularity works best when guided by evidence.

Use remote sensing and smart sampling and direct organic inputs from your circular activities to the trees that need them most.

Multispectral maps (NDVI for young canopies; NDRE for mature ones) guide where compost, frass, and liquid digestate will return the highest marginal gain.

Thermal insights flag water delivery issues before you waste fertiliser on heat-stressed zones that would benefit from water delivery, drainage, or root aeration protocols more than dumping of compost with reckless abandon.

Smart sample waypoints keep leaf, soil, and fruit checks consistent, making trials robust and data reliable. Technologies already available today can help you to keep on top of sampling, results, and your orchard health plans.

This is how technology-first thinking reinforces the sustainability loop.

A simple on-farm blueprint

Week 0-2: Map the flows

Measure average weekly volumes for seeds, peels, pulp, and water. Sketch distances and handling touch-points.

Week 3-8: Two fast pilots

Seed briquettes – sun-dry tests, small press, in-house fuel switch. Track smoke, heat output, and staff feedback.

BSFL starter – one crate stack; feed with pulpy rejects; weigh larvae outputs and frass.

Week 9-12: Decide the energy core

If residues are consistently wet: size a biodigester.

If residues are mostly pits and dry cake: scale briquettes and add a better dryer.

If you have a local buyer for pectin or extracts: trial a bench-top peel line.

Quarter 2: Close the soil loop

Blend frass, compost, and screened digestate. Apply variable-rate in two trial blocks. Track yield, variance, and fruit size distribution against untreated controls.

Commercial side-hustles you can bolt on

Community fuel – sell briquettes into schools and clinics; prioritise clean-cooking partners.

Protein packs – BSF meal for local poultry co-ops; offer frass as a bundle. [Here’s an interesting aquaculture example]

Ingredient sales – pectin or antioxidant extracts to jam makers or nutraceutical kitchens.

What good looks like in 12 months

60–90 % of organic waste diverted from landfill or open dumps.

Diesel, LPG, or charcoal use cut by a measurable margin.

A documented nutrient-return programme per block.

Two paying off-takes beyond your farm gate.

A simple dashboard that links cost, waste volume, energy output, and yield.

Data levers to monitor efficacy and orchard health in the form of smart-app’s and drone-data info.

Circular is not a slogan. It is a set of cash-positive routines that cut waste, power the farm, and feed the soil.

A real-world spark

It is encouraging to see operators like Avotein in Uganda publicly share seed-to-briquette progress and the discipline of moisture management before carbonisation. That is the kind of practical detail rural enterprises can copy; collect pits, dry them well, convert to fuel, and keep the money in the village.

I’ll be sharing South Africa’s own eco-briquette story in an upcoming post later this month, where reusing Macadamia byproducts is the core focus. If you’ve enjoyed the Avocado example, be sure not to miss this one - stay tuned!

Make your own plan

If you produce avocados and want to prototype a bio-circular line, start with seeds, pulpy rejects, and water. Prove one or two of the loops. Then add a third. Build only what your people can operate “on a tough Tuesday in the rainy season” as they say.

The thinking starts here, but the real change starts when we take action.